TSF has in its workshop various high end productive systems for the manufacturing of parts per revolution, mainly parts threaded by rolling. We also have metrology equipments to ensure customer requirements in process, as well as in final product.

In TSF we define stable and reliable processes to always ensure the quality of our products. We are constantly integrating new technologies in each process to be ahead of the current quality standards.

Our certified raw material comes from steelmakers recognized worldwide. This fact allow us to fulfill with our products any international material specifications as ISO, DIN, SAE, JIS, BS and many others.

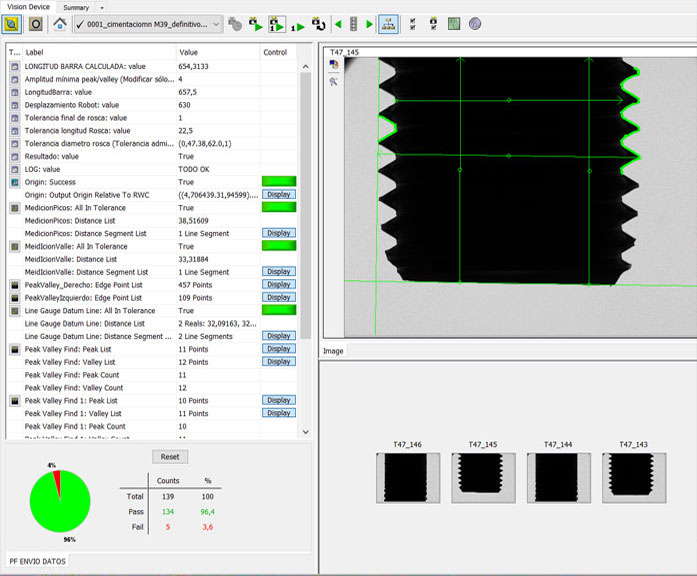

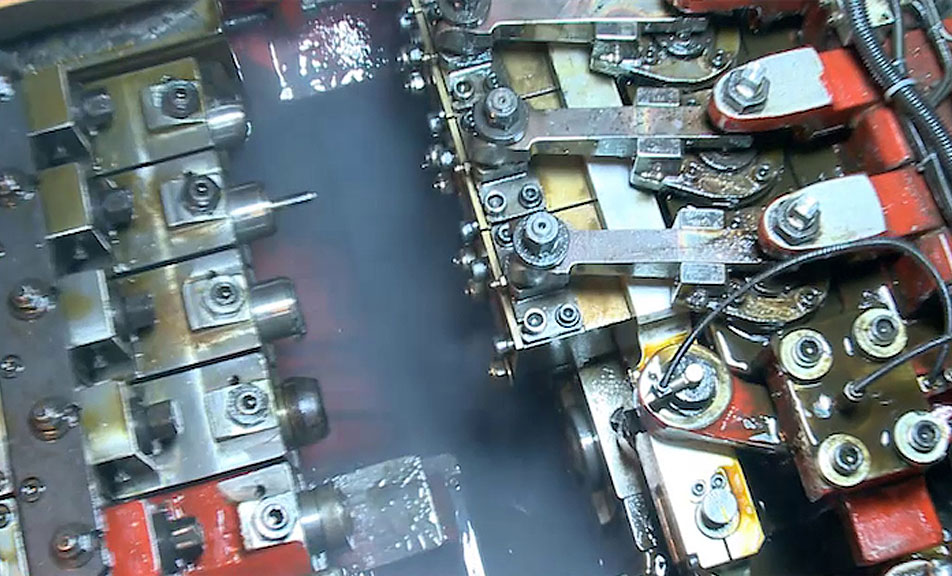

The automation of our production system grants our process capacity and stability, competitively achieving the best quality in our products and a magnificent supply service to our customers.

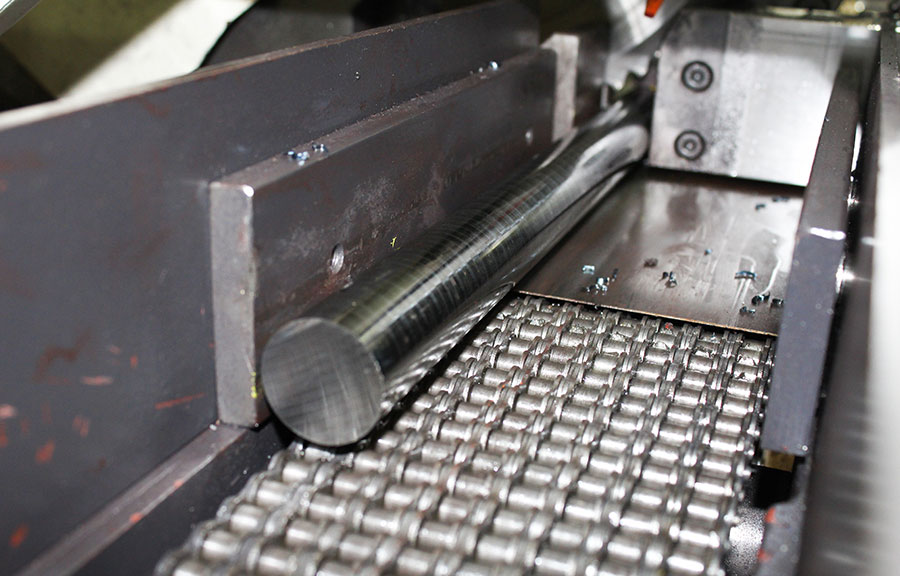

With the use of precise saw equipment, we can provide flat finishing in narrow tolerance window on long bar cuts as well as in repetitive smaller studs.

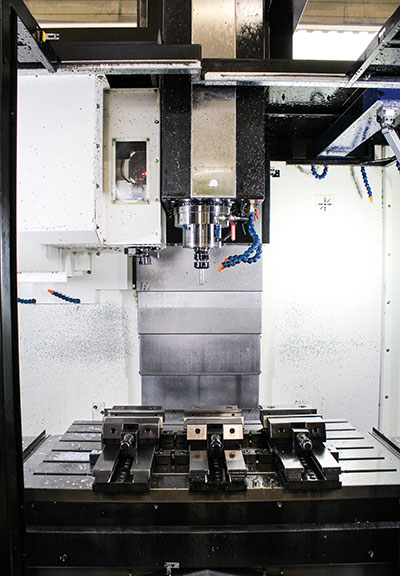

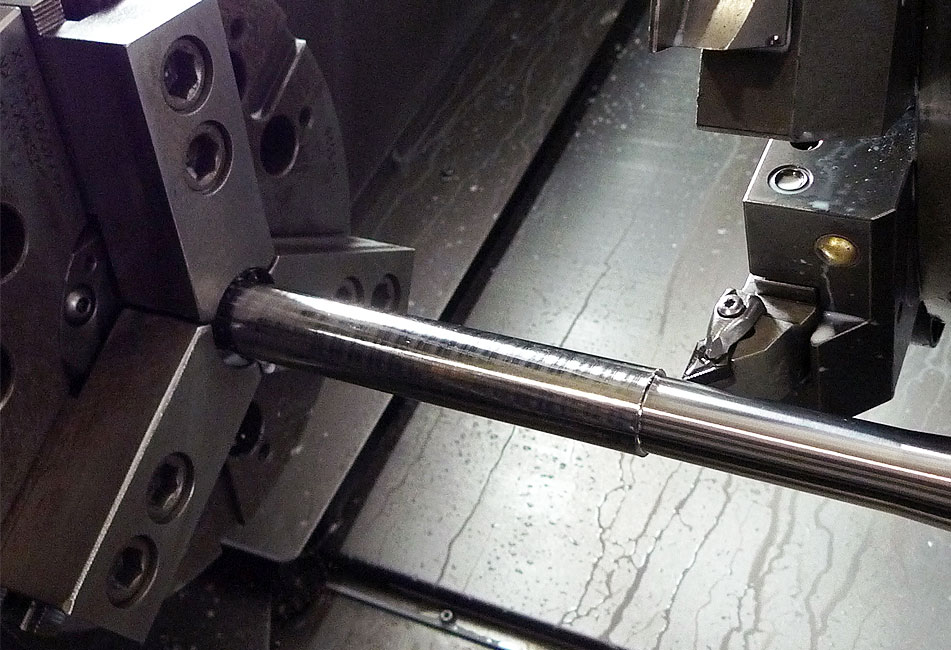

For the manufacture of special parts or carrying out second operations of high accuracy, with this process integrated in TSF , we are capable of offering a quick response in service to our customers.

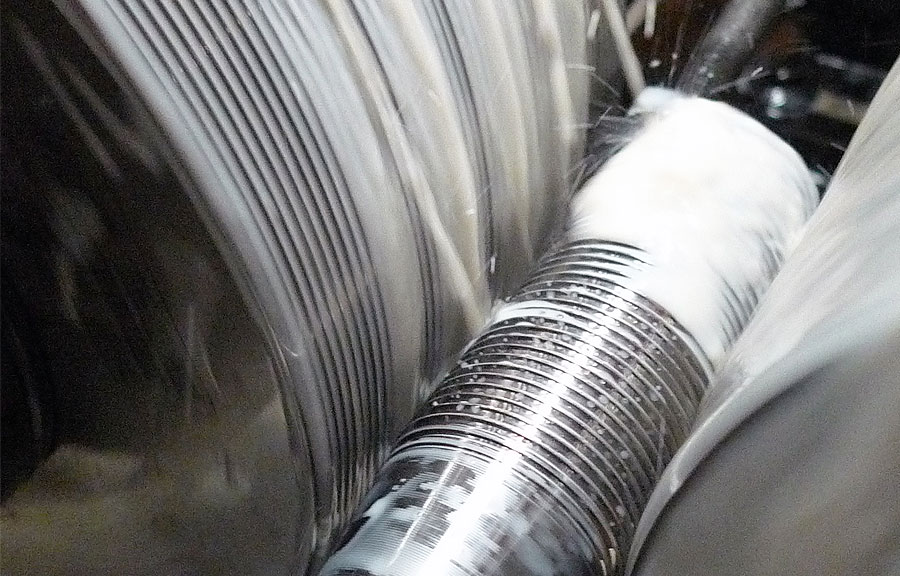

We are able to provide the highest requirements on special parts by thread rolling even after heat treatment, reaching up to 100 mm of diameter under this requirement.

In either cold or hot, we count with long time experience and wide variety of machinery, which enables us to define the most effective equipments to produce the requested items in the most efficient way.

Conveyor or static systems are defined in relation to the type of items to be treated, being always aware of the criticallity of this process to ensure its correct application.

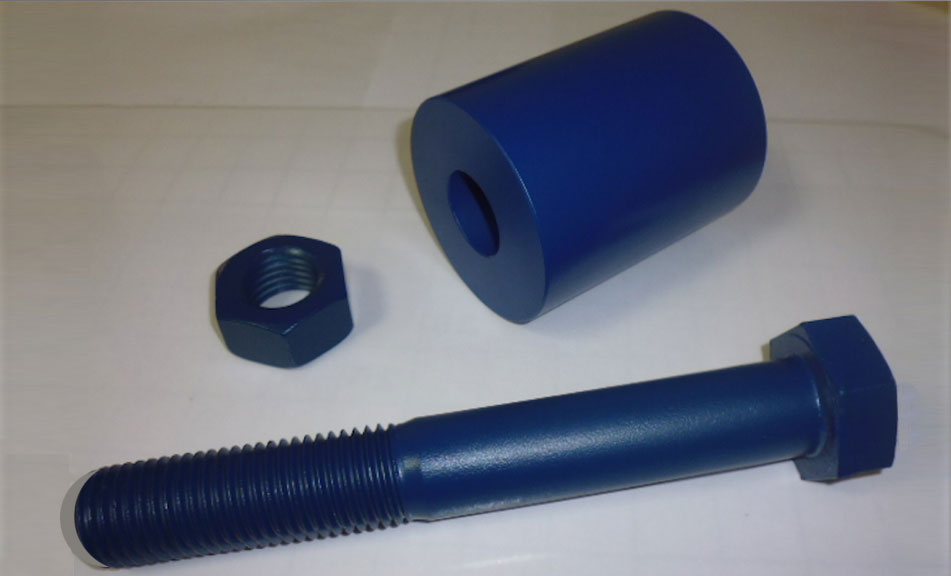

Our long development in the automotive field has instructed us in the most advanced technologies for coating applications. This expertise is also applied to the different kind of finishings required by our customers in their different sectors.

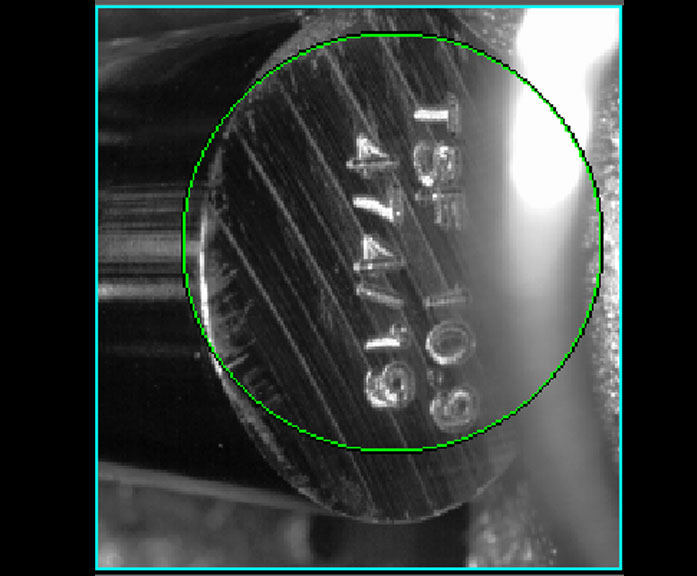

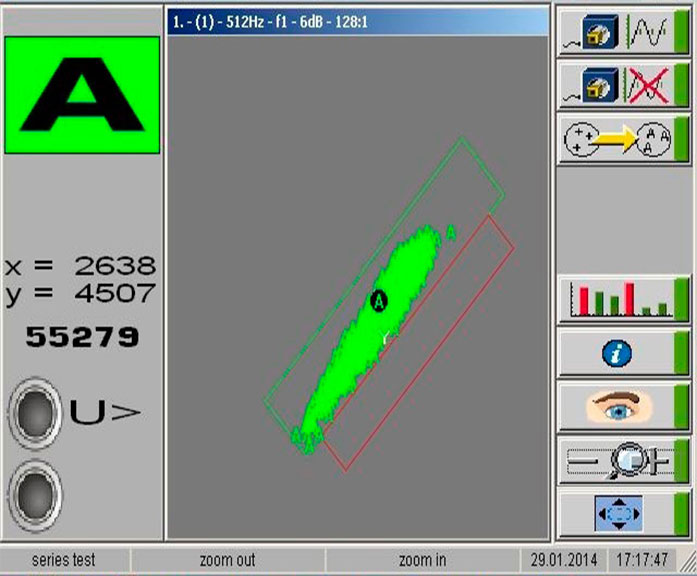

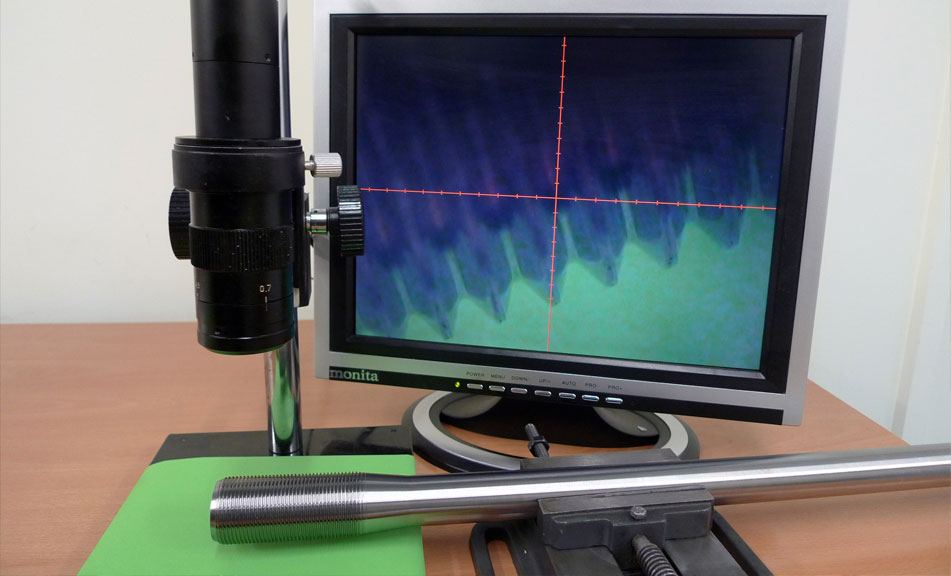

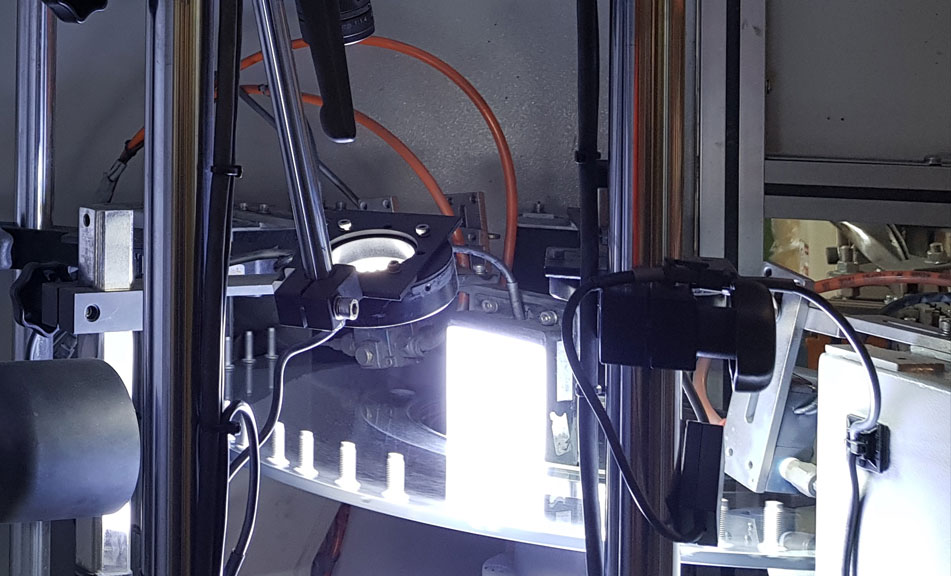

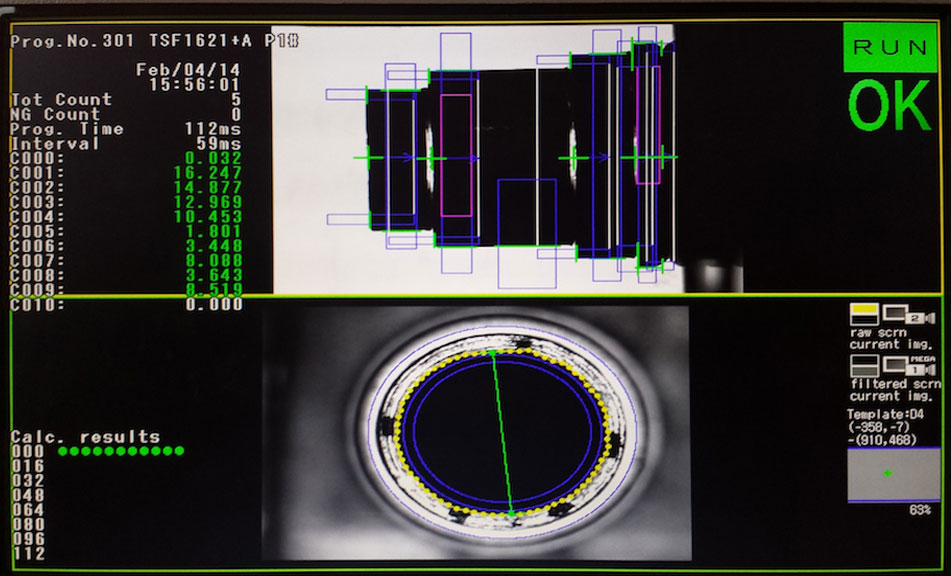

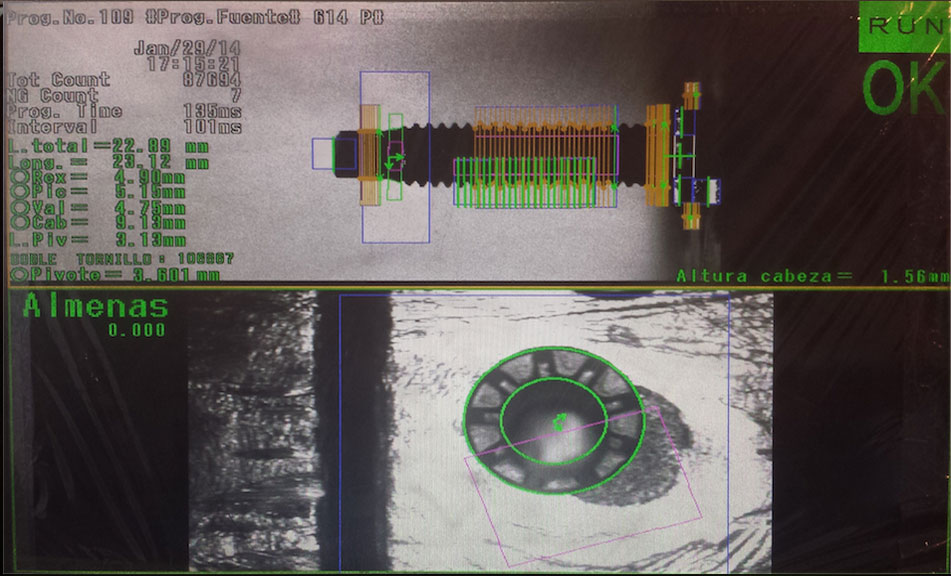

In between our available processes, we count with diverse sorting systems to provide our customers under their request an extra assurance in the materials to be supplied. We count with optical lens inspection equipments for dimensional check and Eddy current systems to guarantee the optimal metalographic structure on safety and high responsability products.